GAS plays a key role in Saudi Arabia’s industrialisation, thanks to Saudi Aramco’s Master Gas System (MGS) which was completed in 1981.

Owned and operated by Saudi Aramco, the MGS made the kingdom self-sufficient in gas feedstocks for industry and fuel for electricity. It also made Saudi Aramco the world’s biggest exporter of gas liquids (LPGs & NGLs). But it had serious problems in the 1980s due to a fall in oil production.

Work on the MGS began in 1975, when the Riyadh government asked then US-owned Aramco to build and operate it as an integrated system.

The company was to recover associated gas produced at the oilfields, process it and supply the gas in dry and liquid forms for both local and export ventures.

Locally, the gas was to feed the two main industrial zones of the kingdom, Jubail on the Gulf and Yanbu’ on the Red Sea. The system was built in two phases. The largest of its kind in the world, the MGS now consists of the following:

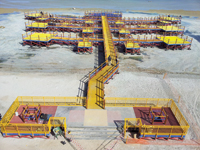

• About 65 gas/oil separation plants (GOSPs) – and some gas compression plants in the various fields, notably including Ghawar, Safaniyah, Khurais, Zuluf, etc. and the Najd fields;

• Pipelines gathering the associated gas for treatment with capacity of 6,000 mmcfd. (The MGS’s capacity was originally set at 5,500 mmcfd. This was scaled down in 1978 to 3,500 mmcfd. Due to increased local demand and occasional shortages of gas feedstocks in the 1980s, it was decided that the gathering capacity should reach 6,000 mmcfd – with big discoveries of non-associated gas at Ghawar having come as added encouragement);

• Three gas processing plants at the Berri, Shedgum and Uthmaniyah oilfields. These plants separate from the gas the methane content which is supplied to the power stations, the refineries and the fertiliser, methanol and metal ventures at the industrial zones. These plants are being debottlenecked and expanded.

There will be two additional gas processing plants, one (the fourth) at Hawiyah to be on stream in late 2001 and one (the 5th) at Haradh to be on stream before 2005. With a total investment of about $7.5 billion, these and a further expansion of the first three plants should by 2005 have the capacity to process up to 9,000 mmcfd.

The two new plants will be processing 2,840 mmcfd of non-associated gas. The other plants are being adapted so they can also process non-associated gas;

• The East-West NGL pipeline which supplies gas liquids from Shedgum to Yanbu’; and

• Two gas fractionation plants at Juaymah and Yanbu’. The fractionators separate ethane, propane, butane and natural gasoline (NGL) from the gas. Ethane is supplied to the ethylene plants, from Juaymah to Jubail and from the Yanbu’ unit to a nearly ethylene complex. The LPGs and NGLs are mostly exported, with local demand for butane having risen due to an expansion of the MTBE sector and demand for propane is to rise rapidly for flexible new crackers being built in the Eastern Province. The Juaymah and Yanbu’ plants are being expanded;

Although the system may gather more than 6,000 mmcfd of raw gas, it recent years it could only process about 4,500 bcfd. To improve and expand the system and increase NGL yields, the $7.5 billion investment was necessary. It was justified thanks to a 50 per cent rise in the price of plant gas to $0.75/mmBtu from the beginning of 1998.

The first MGS phase began operations in 1982, after tests in late 1981. It was then totally dependent on associated gas linked to oil production in a limited number of fields in the Eastern Province. That caused problems because of a fall in oil production.

A further decline in oil production during the subsequent years caused power cuts and a shortage of ethane to ethylene plants. This and other problems compelled Aramco to supplement the system’s gas-feed with Khuff non-associated gas reserves found at Ghawar and cap gas found at Abqaiq in 1984-85.

Both were developed by 1986. The latter element featured the Khuff and Cap Gas Project, completed in December 1986. It consisted of 27 wells and 450,000 feet of flow lines, enabling the MGS to supply 200 mmcfd of additional gas in early 1987.

Phase 2 of the MGS came on stream in late 1984, boosting the supply of associated gas from other oilfields. But gas supply shortages remained because in 1985 Saudi Arabia’s oil production at times fell to 2.5 mbpd. It was not until non-associated gas supplies were added that the MGS was able to meet local requirements as well as feed the fractionation plants for LPG/NGL export.

By 1991 Saudi Aramco had added more than 2,000 mmcfd of non-associated gas gathering capacity to the system, mostly from the Khuff beneath Ghawar. It had installed facilities to produce 450 mmcfd from the Abqaiq gas cap to meet peak demand, and 60 mmcfd from the Qatif storage reservoir for emergency.

But even with these additions, the system’s overall capacity remained limited for two reasons. Gas gathering units were not in place at all the producing oilfields and Saudi Aramco had to flare or reinject substantial quantities of gas.