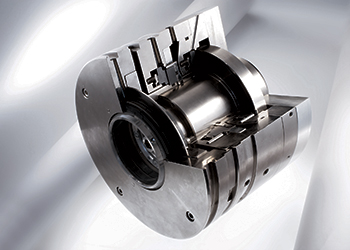

Schneider’s metal seated VariAS-Block ball valve

Schneider’s metal seated VariAS-Block ball valve

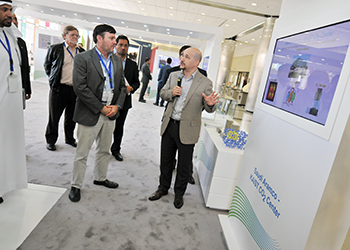

The VariAS-Blocks by AS-Schneider are used in chemical plants and the oil and gas industry among other applications. The pressure must be continuously monitored and measured in the pipework used there

The specialist for industrial valves AS-Schneider has expanded the comprehensive Double Block and Bleed product range of its proven VariAS-Blocks.

These are now also available with a metal seated ball valve design. This means that the valves are suitable for use as a reliable primary isolation in industrial plants – at pressures up to 420 bar and under harsh operating conditions.

The VariAS-Blocks by AS-Schneider are used in chemical plants and the oil and gas industry among other applications. The pressure must be continuously monitored and measured in the pipework used there.

As primary isolation valves on the pressure tapping points, these special shut-off devices serve to reliably separate the impulse lines and process lines from each other. This not only allows reliable pressure measurements, but also protects people and the environment from dangerous and harmful process media. With their sophisticated and compact design, VariAS-Blocks offer numerous advantages over traditional process measurement installations. They combine primary isolation (process side) and secondary isolation (instrumentation side) valves in one single valve body – saving weight and space and simplifying the installation.

|

Schneider’s metal seat |

Potential leakage points are also reduced to a minimum in order to increase safety. Measuring instruments like pressure gauges or transmitters are usually directly mounted on the VariAS-Blocks.

This compact, space-saving mounting minimises the disturbing influence of vibrations, reduces installation and maintenance costs and ensures accurate measurement result. The VariAS-Block type most commonly used is the Double Block and Bleed Design with a primary and a secondary isolation ball valve design and a metal seated needle vent valve.

The VariAS-Block ball valves are available with valve seats made of PTFE Compound or PEEK in the standard version. With the expansion of its product range, AS-Schneider now also offers metal seated ball valves with a bore diameter of 10 mm.

These score above all with their high reliability. Even large temperature fluctuations, pressures up to 420 bar, high contamination levels and aggressive process media are no problem for the metal seats. The new version is also fire safe tested and certified according to ISO 10497 and API 607.

With these features, the metal seated VariAS-Blocks are particularly suitable for use under extreme conditions. AS-Schneider, however, has not neglected the cost efficiency. By using standard components, the manufacturer is able to offer the product at an attractive price. The standard version is suitable for temperatures up to 232 degrees Celsius. VariAS-Blocks are also available for use at higher temperatures upon request.