Application of dry gas seals in the pumping of liquid hydrocarbons

Application of dry gas seals in the pumping of liquid hydrocarbons

Eagleburgmann has always come up with innovative solutions for challenging applications even as companies the world over are constantly looking to increase productivity, efficiency, and performance.

Industrial equipment are subject to harsh conditions and the process must be uninterrupted to meet production goals, but one has to take care to meet emission regulations and see that no leakage occurs, says Biju Chacko, senior sales director of EagleBurgmann Saudi Arabia.

Pumping low vapour margin applications in gas fractioning units, CO2 applications, pump station for downstream handling of NGL fluids products like ethane, propane, butane, iso butane, is a challenge. These need seals to prevent leakage and it poses reliability and safety concerns when using conventional mechanical seals.

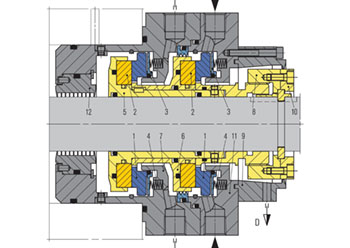

To overcome these situations, EagleBurgmann has developed DF-(P) DGS6 and successfully applied compressor dry gas seal technology with an innovative diamond bonding on the seal faces, he says. Because of the broad seal faces with bi-directional gas grooves, the DF-(P) DGS6 runs contact-free when the media is gaseous. The use of diamond face bonding of the primary seal faces enables the seal to even run dry, but remain wear-free in transient conditions of the medium. If the medium is in liquid state the seal acts like a conventional liquid-lubricated mechanical seal.

Over 200 of these seals have been successfully deployed to date which has resulted in up to an 80 per cent reduction in pump leaks and more than five years of prolonged seal service life. Different versions – single, double, tandem, and tandem seal with intermediate labyrinth arrangement -- are available. Other variants are offered for high pressure and both low and high temperature applications.

OPERATING RANGE SUMMARISED

• Shaft diameter: D = 25 … 280 mm (0.98' … 11.02')

• Pressure: p = 0 … 100 bar (1,450 PSI) (DF-PDGS6: 0 ... 250 bar (3,625 PSI)

• Temperature: t = -30 °C … +200 °C (-22 °F … +392 °F) (DF-PDGS6: -100 °C ... +200 °C (-148°F ... +392 °F)

• Sliding velocity: Vg = 0.6 … 140 m/s (2 … 459 ft/s)

For applications outside the operating range mentioned, please inquire.

RECOMMENDED APPLICATIONS

Oil and gas industry, Refining technology, Petrochemical industry, Hydrocarbon applications, CO2 applications.