Metalock to showcase all types of on-site machining at Sabic Conference 2020

Metalock to showcase all types of on-site machining at Sabic Conference 2020

Metalock Engineering Saudi Arabia aims to provide specialist mechanical engineering services to all types of industries throughout the Middle East.

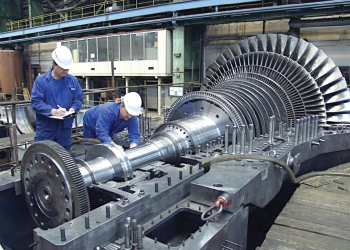

Taking part in Sabic Conference 2020, the company will showcase on-site machining (grinding milling, honing, drilling, etc.); metal stitching; shaft recovery and crankpin and main journal machining; alignment services; welding service and thermal spray.

Offering such a broad range of services to its customers allows the company to support general maintenance activities across an entire range of industry sectors including marine, power generation, steel manufacture, petrochemical manufacture, water, pressings and forgings, food and beverage and general manufacturing.

Founded in 2010 as part of the Midroc Group of companies, the Metalock Group’s on-site machining (OSM) division has built an extensive range of precision portable machining equipment's and specialist skills.

"We provide cost-effective workshop-quality machining for the largest and smallest on-site machining projects around the world. Nearly 70 years’ experience says we can usually solve your machining challenge on-site," says a spokesman.

Always at the forefront of developing new in-situ machining practices, the Metalock Group is embracing workshop machining technologies and transferring them to larger site activities. "We are now able to offer Laser tracking system as part of our range of on-site services," he says.

Metalock Engineering Saudi Arabia is based in Dammam 2nd Industrial Area with a workshop area of 5,000 sq m. The company’s annual turnover is SR25 million ($6.66 million).

Metalock Saudi Arabia operates with its own work force in all sectors and is being supported by Metalock UK for large scale jobs.

The original Metalock company was established 1947 and in the years that have followed the company has become acknowledged as a leading specialist in mechanical repair techniques.

The projects executed by Metalock include repair of steel mill stands, crack repair on compressor casing, machining of devolatiliser shaft, machining of collector ring, roughing mill feed roll modifications and laser levelling of HPSA compressor.