Oil and gas companies are looking to lower monitoring costs

Oil and gas companies are looking to lower monitoring costs

Emerson's Plantweb, put to action by companies around the world, uses data generated by a facility's existing or new sensors and offers analytics tools and secure connectivity to enable scalable monitoring services

Public sector industries such as hotels, banking, and residential facilities have been leveraging third party services (maintenance, logistics, catering, etc) for decades. The obvious reason to outsource work is to reduce costs through third-party experts and execute a service when needed by the customer.

In the Middle East and Africa (MEA) region, oil and gas companies started the outsourcing of assets health and performance monitoring decades ago. However, since companies have equipment from several OEMs (for pumps, turbines, motors, valves, etc) it makes it difficult to manage these assets in a cost-effective manner. This opens the doors for third-party service companies to address the scope of different OEM’s assets in a single contract.

In the past, services like this were difficult to execute. Challenges like data infrastructure, data consolidation and available experts were barriers to effectively monitor various assets. Even if companies or third party service providers were able to acquire data, they had to spend too much time preparing that data to analyse.

In today’s era of digital transformation, oil and gas companies are looking to leverage expert knowledge in real time to lower monitoring costs, improve safety and optimise asset performance and availability.

Emerson, a global industrial automation provider, is addressing the need of the industry by leveraging the power of IIoT (Industrial Internet of Things) to deliver the Plantweb Digital Ecosystem.

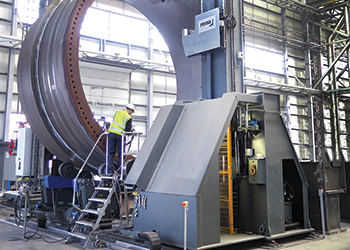

Plantweb leverages data generated by existing or new sensors in a company’s facility and offers analytics tools and secure connectivity to enable scalable monitoring services.

|

Plantweb leverages data generated to enable monitoring |

Emerson offers different service types with consistent delivery, including:

Health Monitoring: Monitoring asset health for sudden changes or alerts. Examples include DeltaV systems, and steam traps.

Condition Monitoring: Monitoring for failure conditions on complex assets such as machines, valves and flowmeters.

Performance Monitoring: Ensuring that an asset is operating or performing as expected. Examples include flowmeters and analysers.

Product as a Service: Providing a full turn-key monitoring solution. Emerson owns and maintains the monitoring equipment and communication network.

Engineered Connected Services: Custom Connected Services offerings built specifically for our customer’s needs.

Emerson has worked with a global energy company for implementing a cloud-enabled monitoring solution for the heat exchangers. The Connected Services solution deployed by the energy company partnering with Emerson was designed to start small, focusing on harvesting and analysing heat exchanger data at one refinery – and even at this scale, the enhanced monitoring solution measurably improved the plant’s operational efficiencies.

The data and recommendations provided by Emerson experts, notes a company representative, helped shift the plant’s maintenance strategy from a reactive to a proactive approach where the appropriate plant personnel are now alerted to issues before they impact operations and are equipped with the information they need to take action.

'Equally important, refinery personnel are now freed from time-consuming monitoring tasks and can more effectively focus on higher-value functions that benefit overall operations,' he says.

That’s the power of enhanced insight, and that’s the power of Plantweb, he adds.

Plantweb has been put to action by companies around the world.

Singapore-based Denka is reducing steam loss and energy consumption thanks to a steam trap-monitoring solution from Emerson Connected Services.

Meanwhile the Chevron Oronite Singapore manufacturing plant is constantly looking to improve safety, reliability, energy efficiency, productivity, and integrity for their next quantum leap in operational excellence. They decided to digitally transform how the plant is run and maintained.

To enable digital transformation, Chevron Oronite deployed Plantweb in phases starting with Real-Time Locating System (RTLS) for rescue locating and geofencing, equipment condition monitoring, steam system monitoring, tablets to access software in the field, and corrosion monitoring.

IT and OT are specialised departments, but for this project they collaborated for a fully integrated solution. As a result they have improved reliability, energy efficiency, productivity, and integrity, and the plant is a safer place to work.

Headquartered in St Louis, Missouri, US, Emerson is a global technology and engineering company providing innovative solutions for customers in industrial, commercial and residential markets. Its automation solutions business helps process, hybrid and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs.

Emerson has actively engaged with MEA national oil companies to provide services to improve the health and performance of their critical equipment. Scaled service offerings allow customers to achieve success and identify opportunities to solve additional challenges in the future with additional monitoring services.