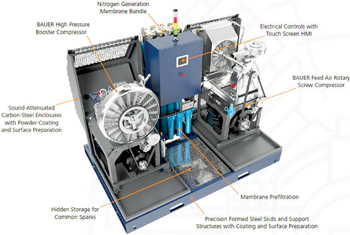

Bauer’s onsite nitrogen generator

Bauer’s onsite nitrogen generator

If a customer has low pressure air source available on site, the company would supply skid for the membranes and booster with optional nitrogen storage tank

The use of nitrogen in the offshore oil and gas industry has decades-long history, and continues to play an integral role in the day-to-day operations aboard mobile offshore drilling units, FPSO’s, and drill ships around the world.

Many applications, such as the blanketing or inerting of storage tanks aboard FPSOs, or the charging of subsea blowout preventer (BOP) accumulators, revolve around safety; others, like the drying of coiled tubing to prevent corrosion resulting from long-term moisture exposure, serve largely economic concerns, says a spokesperson for Bauer Kompressoren.

Without nitrogen, completing these tasks would come at increased operational risk and result in greater costs for operators, she says.

Bauer has come up with a solution to meet the requirements of ‘Onsite Nitrogen Generation’.

'We have maintained the flexibility to produce the nitrogen. For example if a customer has low pressure air source available on site, we would supply skid for the membranes and booster with optional nitrogen storage tank with 5000 psi storage pressure, 98 per cent purity,' she says.

In case low pressure pure air is not available on site, Bauer’s complete integrated solution will be the best option even in offshore conditions.

Some distinctive features Bauer offers on SNG II are user-friendly interactive touch-screen interface pre-programmed maintenance alerts, ROI in approximately two years and even less for extensive uses and continuous availability of gas at high pressure.

For some applications, like blanketing or inerting, nitrogen is required at low pressure of 2 bar. For such requirements, Bauer’s modular option NGM will be a best fit, she adds.

The nitrogen generators in Bauer’s SNG II series are enclosed, integrated and modular complete systems for nitrogen supply comprising Rotocomp screw compressors, nitrogen membrane and Bauer piston compressor.

They are capable of generating pure nitrogen through a nitrogen membrane which provides the basis for high production volume and cost-effectiveness at low costs.

The SNG II series is built from modules on a system frame. The frame makes it easy to adapt the system at any time to meet your individual customer

requirements.

Bauer Kompressoren can look back on more than a century of machine-building experience. Johann Bauer, blacksmith in Arnsdorf (Bavaria), established 'Agricultural Machines Works' in 1888. In 1946 the Bauer Company started building compressors.

Today, Bauer is firmly established as a market leader in the high pressure sector. The company prides itself on having contributed more to the development of breathing air compressors than any other company.

.jpg)