James ... seeing positive changes

James ... seeing positive changes

The company has been invited by Mawani, the Seaport Authority of Saudi Arabia, to take over operations of theKing Fahad Industrial Port in Yanbu and develop it as a container terminal, GSSCO Managing Director RICHARD JAMES tells OGN

Gulf Stevedoring Contracting Company (GSCCO), one of the leading players in the port services sector and the only firm to operate container terminals on both coasts of Saudi Arabia, plans to expand further in the kingdom while it remains committed to developing a best-in-class port and logistical infrastructure across its facilities.

"We are reviewing a number of opportunities for expansion in the kingdom, and are highly optimistic that additional areas for growth will come available in the near future," says GSSCO Managing Director Richard James, a port operations veteran with seagoing experience.

Currently, GSCCO is about to embark on an exciting new venture in the kingdom, with the commencement of container operations at King Fahad Industrial Port in Yanbu. The company has been invited by Mawani, the Seaport Authority of Saudi Arabia, to take over operations of the port and develop it as a container terminal.

The infrastructure is already in place, and GSCCO will be supplementing the equipment to enable the port to provide world-class service levels to the fast-growing market in Yanbu.

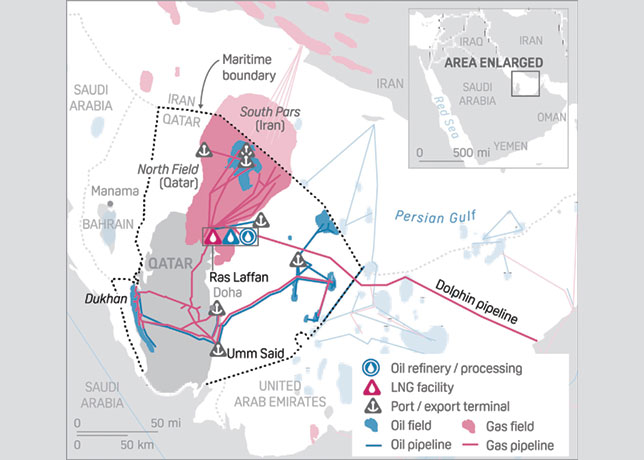

"We are already in dialogue with a number of major exporters in Yanbu, in particular within the petrochemicals sector, and there is great enthusiasm to start exporting their goods over the port," James notes in an interview with OGN.

In its other terminals, GSCCO is working with Mawani to ensure that appropriate investment is put into terminals to make sure that its port infrastructure can support the country’s ambitious goals to develop as the pre-eminent logistics hub along the main East-West trade route, connecting Asia with Europe.

GSCCO, a member of the Gulftainer Group of Companies, is proud to have been at the forefront of the development of Saudi Ports on both coasts of the country for the past 20 years. "As we look at the kingdom’s plans with Vision 2030, we are excited to continue to be a part of this growth," maintains James, who has over 17 years of international work exposure to projects in UK, UAE, Lebanon, Iraq, Russia, India and East Africa.

The impact of the announcement of Vision 2030 has been to galvanise the Saudi population, he explains. It is remarkable to see the extent to which the Saudi youth is embracing the vision of the country as a modern, forward-looking hub for regional activity and economic growth.

GSCCO is seeing very positive changes in terms of governmental activity, with a real energy to execute the vision at all levels within the sectors of government with whom it engages. This is very heartening, as this will be the key to overcoming issues such as the bureaucracy.

GSCCO is entirely supportive of the vision – in particular the fact that Saudi Arabia is pitching to become the primary logistics hub in the region. The kingdom is in an unmatched location, at the crossroads of the main East-West and North-South trading corridors, and Vision 2030’s aim to capitalise on this is extremely exciting at this time. GSCCO’s presence in Jeddah, Jubail and Yanbu positions its better than any other terminal operator in the kingdom to support these long-term aims, he observes.

On the market situation, he says although, business-wise 2018 was a challenging year for marine transport in Saudi Arabia with limited market growth, Jubail saw double-digit volume growth, driven by the ongoing strength of petrochemical exports.

"However, we are seeing strong recovery in the first months of 2019, with import volumes growing consistently. We believe that the seeds planted by the optimism of Vision 2030 are starting to take root, and we see ongoing steady growth for the coming years," he says.

Excerpts from the interview:

What port challenges do you see in Saudi Arabia compared to other parts of the world?

There have been enormous, positive changes in the kingdom in the past 2-3 years, with a huge focus on Vision 2030. While there is great enthusiasm to make Vision 2030 a reality, and thereby to support economic growth and the creation of jobs, there is still an excess of bureaucracy in certain parts of the system. However, what is encouraging is that this is widely recognised, and there is a clear appetite to address and resolve the issue at all levels.

How do you look at the task of ensuring better safety performance at all the ports you handle?

Safety is paramount to all operations within GSCCO. The biggest challenge we face in Saudi Arabia is the fact that our facilities play host to many external contractors – from truck drivers to customs clearing agents to vessel agents – and ensuring that they obey the safety regulations within our facility is key to keeping everyone on the port safe. We have an ongoing programme of safety improvements, from the simplest application and enforcement of rules, such as mandatory safety equipment, to the complete remapping of traffic flows to ensure the segregation of moving equipment and pedestrians on the facility. In a country like Saudi Arabia, a culture of safety is developing; so maintaining standards has needed to be a priority focus. Indeed, we look to the successes of the oil and gas and downstream industries in the country as a benchmark for the fact that safety can be enforced in the most challenging of environments.

What is being done to tackle the issue of greater operational complexity as a result of much bigger ships, next generation vessels?

Vessel sizes continue to increase, with the latest generation of container vessels exceeding 400 m in length, and requiring cranes which can reach containers stacked 10 high and 25 wide on deck. This challenge is one of the issues which we are engaging with Mawani with, to ensure that the necessary investments in port capacity can be made in a commercially viable way, in order to ensure that Saudi Arabia is able to secure its natural position as the primary regional hub.

Managing congestion risk is one of your key jobs. What practices are in place to do so?

Managing congestion is largely a question of communication. The more warning the parties in the supply chain have that there will be peaks in cargo cycles, the more time there is to ensure that any potential bottlenecks are addressed in advance. In this respect, one of the largest challenges that the container shipping industry has today is that information about container flows is often jealously guarded by the various parties, as it is viewed as being commercially sensitive. Certainly, many elements of cargo information is indeed sensitive, but we are starting to see some developments within the industry, on the back of improved technology, to provide much more advance notice between ports on a vessel string of confirmed bookings. We welcome these developments, and GSCCO is engaging with a number of terminal operators in other markets to review how such information flows can be safely shared with a view to providing both better in-transit visibility to the cargo owners, as well as to provide advance warning of any atypical peaks and troughs in cargo flows.

How do you manage to do more with less space?

This is not a significant concern for GSCCO in any of our facilities, as we are fortunate to have significant capacity in all of our facilities in the kingdom and the drive to reduce container dwell times has alleviated this pressure further. Where terminals do have limited space, efficient processes and speed of equipment turnaround are key to ensuring that more can be done with less. Essentially, a well-designed terminal will have an appropriate balance of yard space, quay length and cranes, and room for expansion in line with market growth. For GSCCO in Saudi Arabia, we enjoy this situation across the portfolio.

How do you optimise operations and lower costs to improve productivity?

There is a perception that the best way to optimise operations is to add resources. For instance, on a container terminal, to offer faster container handling rates on a crane, there is an argument for adding terminal trucks to feed the crane. While, to a degree, this is effective, there is more value to be had from planning and communication. These are at the heart of efficient, productive operations. A close coordination with our shipping line customers in advance of vessel arrival is key. But beyond this, the efficient management of both yard and vessel stowage are the work of our experienced and talented planning and operations teams. This, coupled with the well-earned trust that our team has from the shipping lines, ensures that we are often able to recommend more efficient stowage and operational cycles to our customers, thereby increasing productivity without raising costs.

What is your strategy to ensure that you stay profitable through shipping line economic cycles?

Within the shipping industry, all parties are to a degree exposed to the significant variations in economic cycles. In recent years, one of the biggest challenges has been that the shipping industry has constantly added capacity at a rate far in excess of market growth. This has had the effect of not only depressing rates for shipping lines, but has also put significant pressure on terminal operators, who have been in the unenviable position of needing to invest in larger facilities and cranes to support the bigger ships. At the same time, changes to shipping alliances has meant that the number of effective customers for terminals has reduced from over 20 individual shipping lines just a few years ago, to effectively only three major alliances in 2019, reducing competition and enormously increasing the buying power of these alliances. Staying profitable therefore as a terminal operator is driven by a combination of optimisation of efficiency and a great focus on service levels – both in terms of speed of operations, but also in the softer areas, of communication and visibility, where the shipping lines’ own customers benefit from a terminal’s superior service.