The GPC team led by Khonaini (fourth from left) after signing the deal with Haeusler

The GPC team led by Khonaini (fourth from left) after signing the deal with Haeusler

With this ambitious expansion plan, the Jubail-based leading pipe manufacturer is also targeting the international market as the proposed new line will impart the company more flexibility in the execution of manufacturing orders

Jubail-based Global Pipe Company (GPC), a leading pipe manufacturer, plans to invest SR100 million ($26.65 million) in setting up a new manufacturing line that will double the company’s annual production capacity from 200,000 tonnes to 400,000 tonnes.

During the last board meeting held in Germany in May 2017, the board of directors approved the investment for the new manufacturing line for GPC’s Mill in Jubail. The Board also fixed a tight schedule for the erection and commissioning of this new line that should be ready for production in the third quarter in 2018, says GPC managing director Ahmed Hamed Al-Khonaini in an interview.

The new line will impart GPC more flexibility in the execution of manufacturing orders. 'It will be implemented as a completely independent line from the existing line. This will allow us to run two different manufacturing orders simultaneously and avoid interruption in case of priority changes,' explains GPC general manager Maher Fkaier.

'Our experience with Aramco’s Master Gas Project showed us that a higher output is required from the pipe manufacturer involved to feed the coating yards and also the pipe stringing activity at the project site,' says Khonaini. Located at the beginning of the supply chain for line pipe projects, GPC wants to be the driving partner for these jobs.

Asked about the rationale of this new investment at a time when the oil and gas sector was experiencing a downturn, Khonaini says: 'In our local market, we don’t see the general downturn observed in the international markets. We are handling an increasing number of enquires for new projects from Saudi Aramco for the near-term and the long term.

The in-Kingdom Total Value Add program (IKTVA) initiated by Saudi Aramco is giving us confidence, that these new jobs will be awarded mainly to local suppliers. At the same time, we are aware that significant quantities of pipe orders are awarded to manufacturers outside the kingdom. For the Master Gas Project Expansion II, about 40 per cent of the pipes required have been sourced from pipe mills outside Saudi Arabia. With our new expansion and increased capacity, we are aiming to grab a significant portion of the pipes outsourced.'

With this ambitious expansion plan, GPC is also targeting the international market. 'Inspired by Saudi Vision 2030, GPC is aiming to explore new opportunities in the GCC and Mena region. The proximity to these markets and the high quality Aramco standards GPC is applying, are making its products attractive to these neighbouring markets. By doubling the nominal capacity, we will be in a position to allocate production slots for these markets without neglecting the home market, he says.

Doubling the nominal capacity could have been easily achieved by simply doubling the existing machines. However, since GPC was also targeting productivity increase and more flexibility with independent manufacturing lines, a detailed study was done to identify the required equipment.

'Based on pipes sizes involved in orders and RFQ’s we have received during the whole period of operation, we have undertaken a detailed analysis of pipes dimensions and material grades involved. The analysis showed that a major share of our market consisted of big diameter pipes with quite lower thickness. For this reason we selected a Three-Roll-Bending machine as the main forming machine for the new line,' explains Fkaier.

'With the JCO press available in our existing line, we have the flexibility to cover the whole size range from 16 inches to 62 inches, but with lower productivity for bigger diameter pipes. The Roll Bending Machine cannot form small diameter pipes, but has a significant higher output for big diameters. On the other hand, the detailed study has shown us that our existing line is also having some limitations to provide pipes with smaller diameter and heavier thickness.

'The Post-Bending machine in the existing line is not in a position to make round straight ends for heavy thickness pipes after forming at the JCO press. For this reason, we have considered a pre-bending machine in our expansion plan. This machine will be placed in front of the JCO-Press and will pre-bend plate ends after edge milling. The new pre-bending machine will serve the existing line with the JCO-Press to provide smaller diameter pipes with heavy thickness. The existing post-bending machine will be shifted to the new line to serve the new three-roll-bending machine providing bid diameter pipes with lower thickness,' he says.

In order to have a completely independent pipe flow in the new manufacturing line and less interaction between the lines, GPC decided to add a new Tack-Welding machine to close pipes after forming. The new tack-welding machine will have a similar capacity like the one in the existing line with additional laser tracking feature allowing the welding electrode to follow the seam automatically.

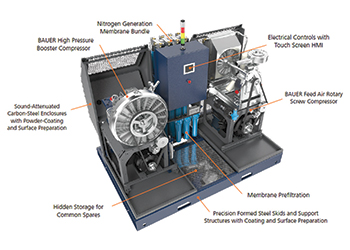

The new line will also have its own expander in the final control area. In addition to the stress relief on welded pipes, the expander is giving the final shape for GPC’s products making sure that the final dimensions are within the required range according to the specifications. The new expander machine will cover the diameter range between 24 inches and 56 inches and optimise GPC’s output in big diameter pipes.

The new Hydrotesting Machine is also one of the major equipment in the new line. The new hydrotester will have the extended capacity of 650 bar allowing hydro-inspection of heavy thickness pipes as per specifications.

The new line will have also its own NDT equipment. Two ultrasonic testing machines for internal and final inspection are part of GPC’s investment programme for the new line, as well as an X-Ray Bunker for pipe end inspection as per applicable specification.

GPC will add also several overhead cranes and pipe conveyer systems connecting the new machines to a powerful manufacturing line and simplifying the production logistic, says Fkaier.

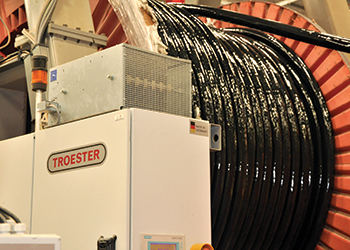

GPC has selected leading European machine suppliers for the equipment for the new line. 'One of the main features of our investment plan is to maintain the technology leadership in our market,' explains Khonaini,

'Our target is to equip our new manufacturing line with the most advanced technology available on the market from reliable machine suppliers with long experience in the supply of equipment for pipe mills,' he says.

GPC collected offers from several well-known machine suppliers. The final decision was made based on the liability of the supplier and the ability to provide machines meeting the requirements of GPC in terms of size range, good quality of pipes and good output. GPC placed the Three-Roll-bending and tack-welding machines with Haeusler AG in Duggingen Switzerland. The Swiss-German machine supplier has a vast experience in the supply of these machines and building the forming area in the new manufacturing line. 'With about 26 similar roll bending machines, we think that Haeusler is the right supplier for this kind of equipment for our investment,' adds Fkaier.

SMS Group GmbH in Moechengladbach in Germany was selected as supplier for the Expander and the Hydrotesting machines. 'Having supplied 17 Expander Machines from 2002 and 19 Hydrotesters from 1971, SMS Group presented us strong references in pipe mills with a similar scope of business,' he says.

Local content was one of the major criteria for GPC’s machine supplier selection. 'All selected suppliers are having their own branches in the kingdom. We had insisted that the local units are part of the whole negotiation process and that the contracts for installation and erection of the machines were signed with a local unit,' says Khonaini.

'With this approach, we will support the international machine suppliers to build local subsidiaries in the kingdom and transfer the required know-how. This will improve our access to aftersales services and spare parts,' he adds.

After signing contracts for sourcing of long lead items for the new line, GPC has also awarded the civil works. 'We have a tight schedule and we have to get all foundations for the new machines ready before end of the second quarter 2018,' says Fkaier. He added further:

'The first foundation for the Pre-Bending machine is already under execution. We have to be very careful during the construction of the new foundations. The manufacturing activity in our existing line shall not be disturbed. A detailed and accurate planning is required.'

MASTER GAS PROJECT

During the last 15 months, GPC had worked almost exclusively on the Master Gas Systems Expansion II project. About 550 km from the total quantity of about 900 km of pipes required for this project were allocated to GPC.

The main size required for MGS-II is 56 inches and wall thickness ranging from 14 mm to 26 mm. Even though the required sizes, with big diameters and low thickness, are very challenging for the LSAW manufacturing process, Khonaini says: 'GPC finished the manufacturing activities within 15 months.' After some issues it faced at the beginning of the project in June 2016, GPC developed an ambitious action plan to improve its mill’s output and productivity.

'We developed a new forming procedure for big diameter pipes for our JCO press, based on a wide shoe reducing the number of bending strokes. We also added an additional X-Ray Banker to our manufacturing line and, last but not least, we added some conveyer systems for plates and pipes to improve the manufacturing logistics and remove some bottlenecks in our manufacturing line,' says Fkaier.

After putting in place all these measures, it was possible to increase the output to reach an average of 160 pipes per day. 'This is a major improvement comparing the maximum output of 80 pipes per day at the beginning of the project,' adds Khonaini.

The last MGS-II pipe left GPC’s manufacturing bench by the end of September 2017. The company is working now on a new job for Saudi Aramco involving Sour-Service pipes in 20 inches and 24 inches and wall thickness ranging for 15 mm to 19 mm. The total quantity of about 6,000 tonnes is required for Saudi Armco pipe store replenishment.

Meanwhile, GPC has recently won a new major pipeline contract from Saudi Aramco. The Arabian Heavy Oil Corridor project has been awarded to the mill in Jubail. The scope of supply contains three items of pipes with the diameter of 48 inches and wall thickness ranging from 15 mm to 22 mm. The total length in 165 km including about 80,000 tonnes of X65 steel material. The delivery of pipes is schedule between mid-December 2017 and March-April 2018.

.jpg)